6.4 Construction of drilled shafts

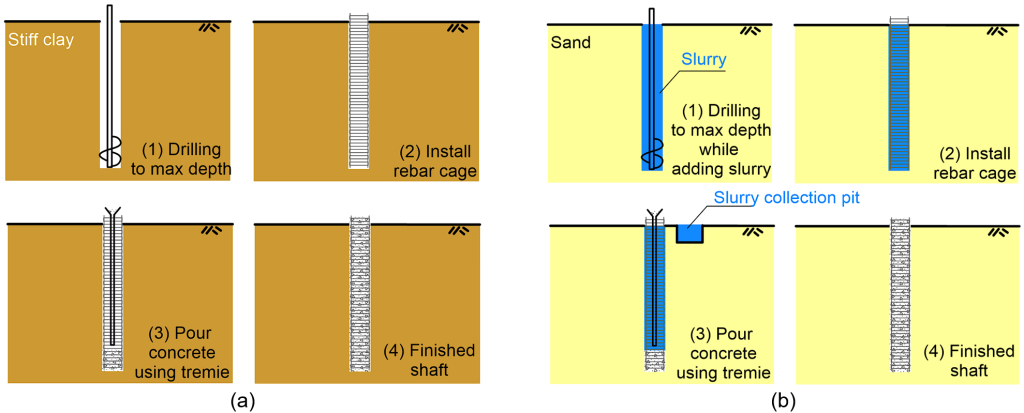

6.4.1 Dry construction (unsupported non-displacement piles)

In stable soils that will not cave in or deflect inward when the shaft is drilled to its full depth, such as stiff clay, the dry method of construction may be employed (Figure 6.10a). A temporary surface casing may be placed after excavation has advanced for a couple of meters, to prevent raveling of soil into the shaft, and act as a guide for drilling works. The pile may not be reinforced along its entire length: in some cases, the lower part of the pile may be constructed from unreinforced (plain) concrete, as bending stresses at that depth are low to negligible. The length of the pile requiring reinforcement, and the amount of rebars, will always be dictated by appropriate calculations.

6.4.2. Wet construction (supported non-displacement piles)

The wet method of construction (or slurry method, Figure 6.10b) is based on the use of slurry to fill the drilled shaft until excavation reaches the maximum depth. The rebar cage is placed directly into the fluid-filled shaft. The tremie concrete pouring method is used, to pour the concrete below the slurry level, so that the rising concrete displaces the slurry to the top, without washing out the cement content. The concrete mix design is of utmost importance for the successful application of the method.

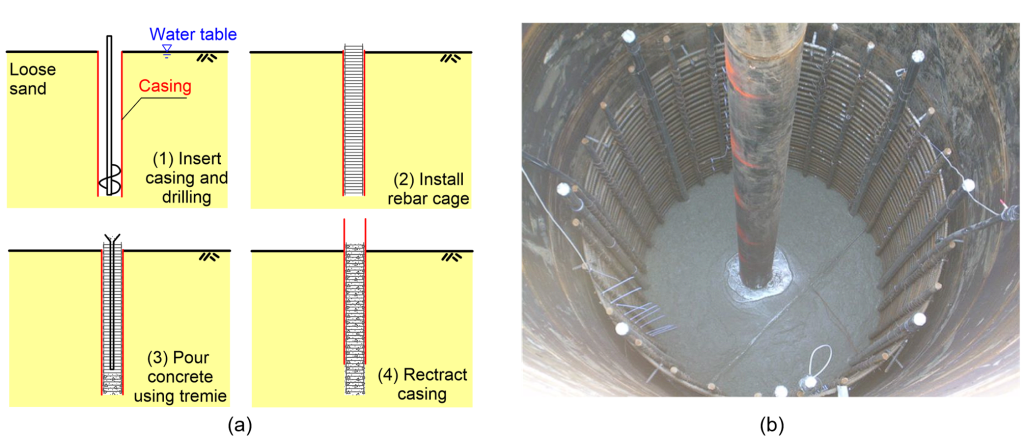

6.4.3. Casing construction (supported non-displacement piles)

An alternative to the wet construction method when caving soils are encountered (e.g., loose saturated sands), is the casing method of construction (Figure 6.11). Casing of the shaft prevents cave in of the soil, and is used as a guide for drilling. After the shaft is filled with concrete, the casing is retracted (or in some cases is left in situ). The fluidity of the concrete is very important, so that the drilling fluid (slurry) will be ejected from the excavation, which must be completely filled with concrete. Care must be taken so that disposal of the slurry meets environmental standards.