6.3 Installation of driven piles

Driven piles are usually installed by means of an impact hammer. The pile type and hammer are selected while considering several factors such as the loads to be supported, tolerable noise and vibrations during construction, inspection requirements, available time, possible corrosion issues etc. Additional aspects should be also considered such the possible drift of piles during driving, which depends on the bending stiffness of the pile relatively to the stiffness of the soil, optimisation of the number or piles/of the pile length ratio etc.

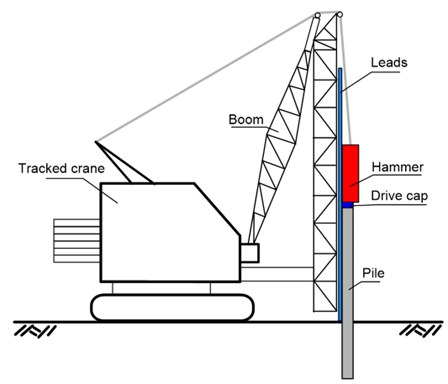

Before pile driving commences, a continuous-flight auger may be used to pre-drill a small diameter hole, and facilitate driving through certain formations. The hammer is attached on the top of a crane, using leads to align the pile relatively to the hammer, and achieve verticality (Figure 6.9). Today, steam or pneumatic hammers are used in most projects, instead of simple drop hammers, to increase productivity.