1.5 The Standard Penetration Test (SPT)

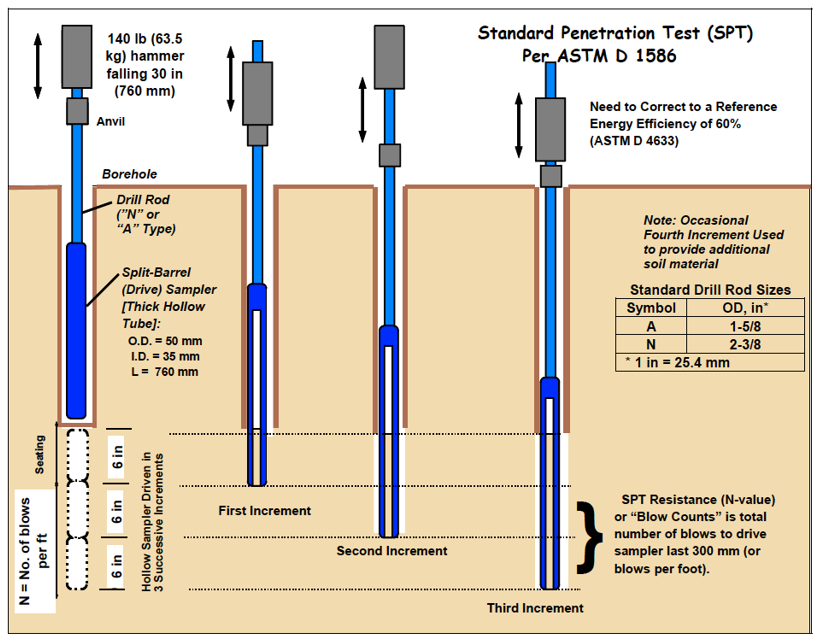

The most common method of in situ soil testing is the Standard Penetration Test (SPT), used globally. It has its origins in Boston, USA of the early 20th century, and was first used by one Charles Gow. Gow was the first one to drill exploratory boreholes using 1-in diameter drive samplers (similar to the one shown in Figure 1.9). Up to that point, contractors used cuttings from wash borings to delineate the interface between soil and bedrock, as they used drilling methods similar to the ones used to drill water wells. Harry Mohr, one of Gow’s engineers, standarised the procedure, and started recording the number of blow counts required to advance a 2-in sampler with a 140-lb hammer dropping 30 inches. Karl Terzaghi, arguably the father of Soil Mechanics, liked the idea and later developed correlations between the allowable bearing pressure and the number of blowcounts. The standard SPT procedure (Figure 1.13) presented herein is described in detail in AS1289.6.3, and hasn’t changed much from Mohr’s testing procedure.

In short, a 2-in (50 mm) split-barrel sampler is driven into the soil by dropping a 140-lb (63.5 kg) hammer from a height of 30 in (760 mm). The hammer is dropped repeatedly, until an ultimate penetration of 18 in (450 mm) is achieved. The number of blows of the hammer are recorded during 6 in (150 mm) penetration intervals. The necessary number of blows for advancing the sampler to the last 12 in (300 mm) is the SPT N- value (Figure 1.13). For example, during a SPT test, the following values were recorded:

- 5 blows/150 mm

- 6 blows/150 mm

- 10 blows/150 mm

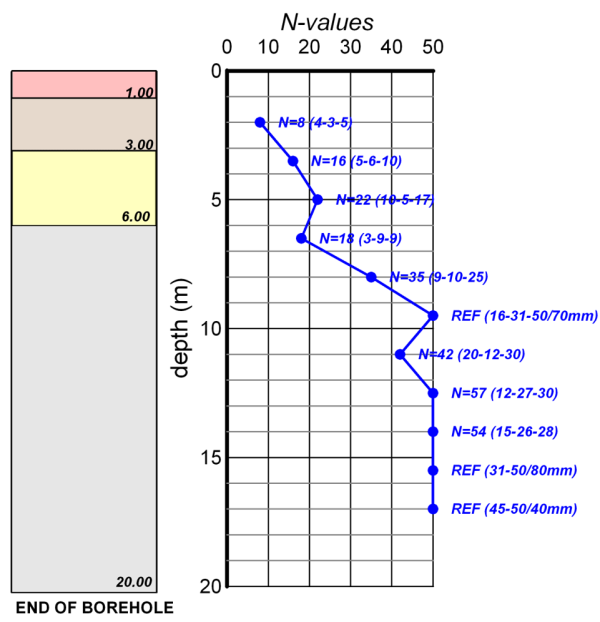

Blows from the first 150 mm of penetration are disregarded, to account for soil disturbance due to boring, thus the N-value is equal to N = 6+10 = 16 (Figure 1.14).

The test is halted to prevent damage to equipment, and refusal (REF) is reported on the boring log if:

- More than 50 blows are required for any 150 mm increment.

- More than 100 blows are required for the last two increments.

- 10 successive blows produce no advance.

When the full test depth cannot be achieved, the boring log will report a ratio similar to 50/40 mm, indicating that the last 50 blows resulted in penetration of the sampler equal to 40 mm (Figure 1.14). After the test, the soil sample is retrieved, and is usually used for laboratory classification tests.

Several boring techniques can be used in combination with the SPT tests, such as continuous flight hollow stem augering, wash boring etc. provided that care will taken so that soil beneath the advancing borehole is not significantly disturbed during drilling. SPT tests are performed about every 1.5 m, unless otherwise dictated by soil conditions e.g., encountering very stiff to hard formations, or sampling needs (undisturbed sampling).

Based on the soil type, characterised by the retrieved sample through laboratory classification tests, and the number of blow counts, empirical correlations have been proposed that provide the in situ soil shear strength and compressibility properties. This implies that there is a unique correlation between the penetration resistance and the mechanical characteristics of the soil.

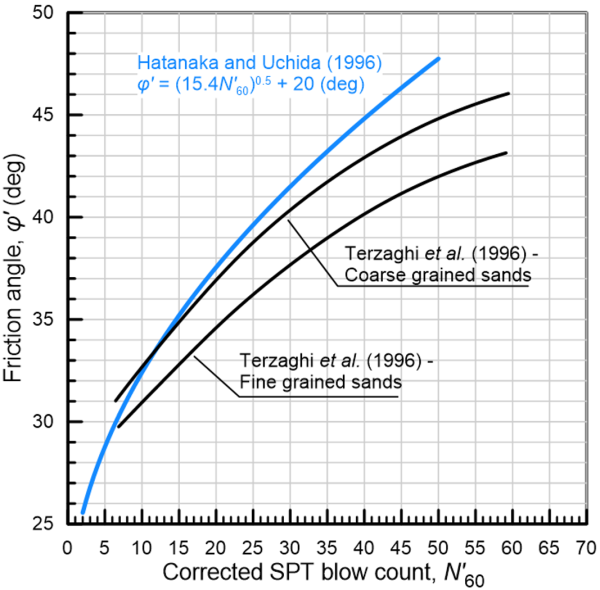

Many of these correlations, which are useful in everyday geotechnical engineering practice in lack of more advanced test results, require as input the corrected SPT blow count, N′ (often referred to in the literature as Nl), as the ones presented in Table 1.3. Corrected blow counts account for the in situ geostatic stress state of the soil, at the depth where it is tested. For example, sands of identical mineralogy, structure and density will appear stronger and exhibit higher blow counts at greater depths, than when tested at shallower depths, due to the effect of confining stresses. Thus, some soil properties that are derived from SPT test results, such as the unit weight or the friction angle, may be better estimated if we normalise blow counts to remove overburden effects. Note that some correlations, such as the ones provided in Table 1.4, require as input the uncorrected blow counts.

| Corrected SPT N’ | Description/ consistency | Soil parameters | ||

|---|---|---|---|---|

| Sand | Relative density Dr (%) | Range of bulk unit weight γ (kN/m3) | Range of friction angle φ‘ (deg) | |

| 0 | Very loose | 0 | 11.0 to 15.7 | 25 to 30 |

| 4 | Loose | 15 | 14.1 to 18.1 | 27 to 32 |

| 10 | Medium | 35 | 17.3 to 20.4 | 30 to 35 |

| 30 | Dense | 65 | 18.8 to 22.0 | 35 to 40 |

| 50 | Very dense | 85 | 20.4 to 23.6 | 38 to 43 |

| Clay | Range of bulk unit weight γ (kN/m3) | Undrained shear strength Su (kPa) | ||

| 0 | Very soft | 15.7 to 18.8 | 0 | |

| 2 | Soft | 12 | ||

| 4 | Medium | 17.3 to 20.4 | 25 | |

| 8 | Stiff | 50 | ||

| 16 | Very stiff | 18.8 to 22.0 | 100 | |

| 32 | Hard | 200 | ||

Eq. 1.1 is used to correct N-SPT blows to the effective vertical geostatic stress at the depth of the test σ′z0:

(1.1) ![]()

where the correction factor CN is calculated as:

(1.2) ![]()

| Uncorrected SPT N | Bulk unit weight y (kN/m3) | Friction angle φ′ (deg) |

|---|---|---|

| 0-2 | 15.7 | 26 |

| 3-4 | 15.7 | 28 |

| 4-10 | 16.5 | 29 |

| 10-20 | 17.3 | 30 |

| 20-30 | 18.1 | 32 |

| 30-40 | 18.9 | 33 |

| >40 | 19.6 | 34 |

The actual energy transmitted through each SPT blow, and thus of course the penetration achieved, depends also on the equipment used (Figure 1.15). Gunaratne (2006) identifies the following factors affecting the number of blow counts:

- Hammer efficiency

- Length of drill rod

- Type of sampler

- Borehole diameter

Values of N′ can be further normalised over a standard hammer efficiency E, so that results from SPT tests performed with different equipment are comparable, and can be used in empirical correlations:

(1.3) ![]()

where different factors ni (n1 to n4) account for the effect of the abovementioned parameters, if the test is not executed in a standard way, as per AS1289.6.3.1. Furthermore, as the standard hammer efficiency is E = 70%, it is:

(1.4) ![]()

so the ni value to convert blow count number to other common efficiencies e.g., 60% is directly proportional to the ratio of the corresponding efficiencies:

(1.5) ![]()

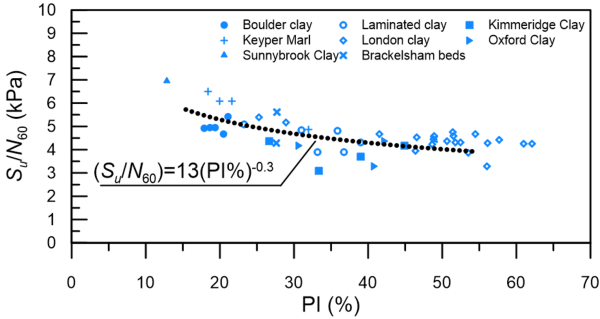

As SPT testing is simple, cheap and is performed while drilling most exploratory boreholes, numerous correlations have been proposed in the literature for estimating different soil parameters based on SPT blowcounts and soil type. Such correlations, as the few widely used ones shown below, are useful for estimating soil parameters when limited laboratory test data are available, or for cross-checking the reliability of laboratory tests. However, when using them one needs to appreciate their crude, empirical nature, the scatter of fitted data, and the lack of a robust theoretical interpretation model for converting “blow counts” to stiffness or soil strength parameters.

| Soil | Drained E′ or Undrained Eu Young’s modulus (kPa) |

|---|---|

| Sand | E′ = (2600 to 2900)N |

| Gravelly sand | E′ = 1200(N+6) |

| Clayey sand | E′ = 320(N+15) |

| Silt, sandy silt or clayey silt | Eu = 300(N+6) |

| Low plasticity clay (PI<15%) | Eu = 1200+580N |

| High plasticity clay (PI>15%) | Eu = 400+1150N |